The air in the packaging facility hums with a sterile, almost clinical efficiency, but something feels off. Not the steady whir of the new machine, which cost a cool $1,000,004 and gleams under the fluorescent lights, but the fine, insidious dust that constantly, persistently settles. It’s everywhere. It clogs sensors, scuffs finished goods, and, worst of all, causes micro-stoppages the manufacturer can’t explain. They’ve run every diagnostic, tweaked every parameter, yet the machine still pauses, sputtering, as if catching its breath on an invisible particulate. The problem isn’t the shiny new jewel; it’s the foundation – a 24-year-old concrete slab, slowly, subtly, crumbling beneath its feet.

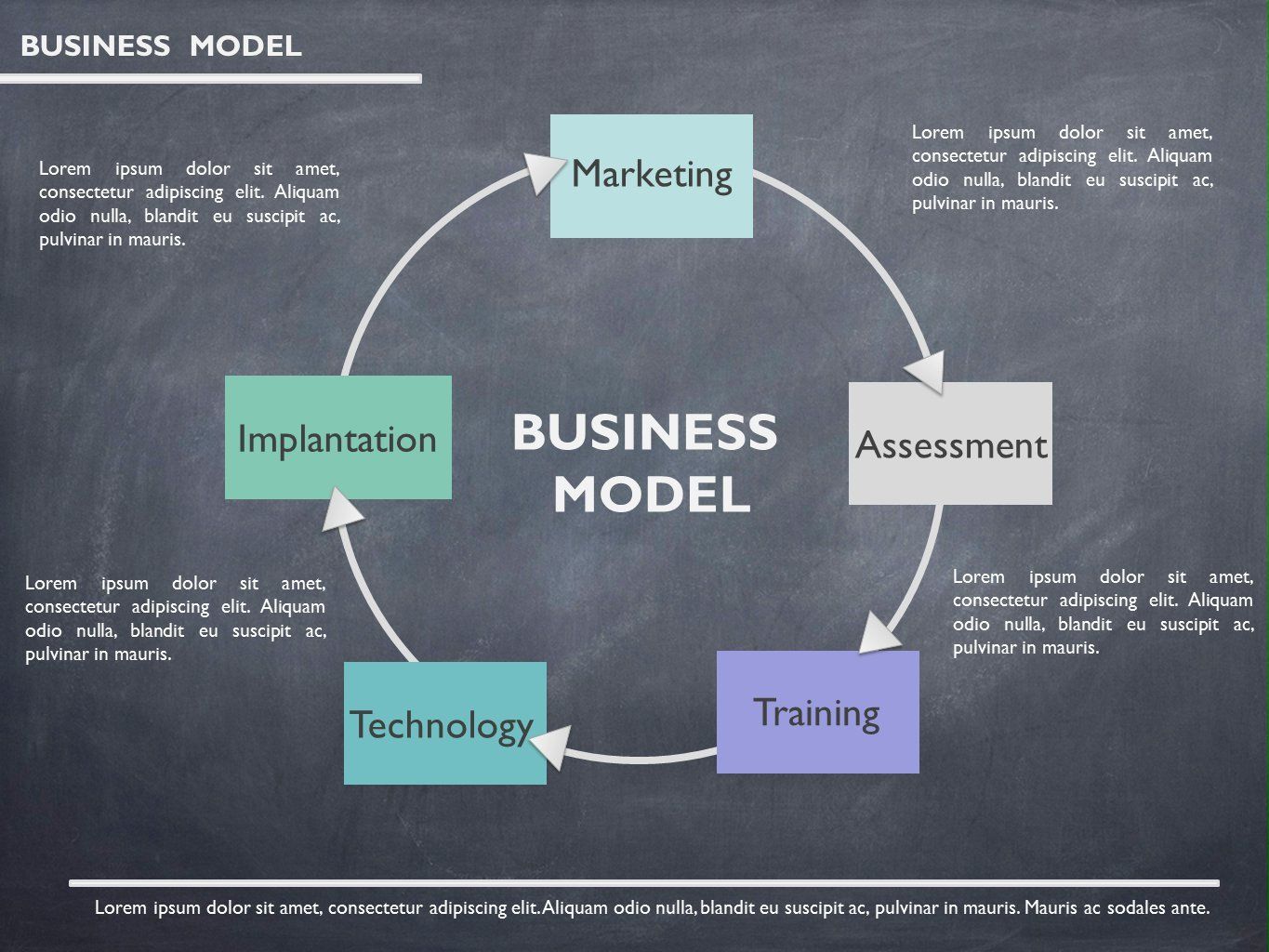

We’re so good at talking about technical debt in software. Every hurried patch, every postponed refactor, every shortcut in code creates a debt that compounds, costing exponentially more down the line. We acknowledge it, even if we don’t always address it. But when it comes to the physical world, the bricks and mortar, the pipes and wires, the very ground our operations stand on, we seem to have a collective blind spot. This isn’t just technical debt with a different name; it’s infrastructural debt, and I’ve become convinced it’s

far more real, far more insidious,

than any balance sheet can capture. It’s the silent killer of productivity, the unacknowledged thief of morale.

Daniel D.’s Proofing Room Predicament

Take Daniel D., for example. He’s our third-shift baker, a man whose hands know the dough better than any machine ever will. His job is to ensure the first batch of artisan bread hits the ovens by 4:00 AM, ready for the morning rush. For the past 4 months, though, Daniel has been wrestling with an inconsistent proofing room. Not the temperature, that’s digitally controlled. It’s the floor. It sags slightly in one corner, just enough to throw off the delicate balance of the proofing racks.

He jury-rigs shims from scraps of cardboard, pushing and pulling, trying to compensate for what should be a perfectly level surface. His frustration isn’t with the recipe or the oven. It’s with the underlying instability that forces him to spend 24 minutes every single night fixing a problem that shouldn’t exist.

The Blind Spot of the Visible

It’s easy to point fingers, of course. To say, “Why don’t *they* fix it?” But I’m as guilty as anyone. Just the other day, I was so focused on installing new, high-tech security cameras at my own place – all about the flashy, visible protection – that I completely overlooked the rotting sill beneath the main door. I actually walked right into the edge of a newly installed glass panel, not seeing it in the morning light, still thinking about the camera feed, completely oblivious to the worn-out step that could have been a trip hazard.

It felt exactly like a physical manifestation of this blind spot, a jarring reminder that sometimes the most obvious dangers are the ones we neglect because they’re not “exciting” or “new.” We fetishize the visible, the upgrade, the latest model, while the very foundation crumbles, often with a cost far greater than just a bruised ego or an unexpected repair bill. It’s not just money; it’s the invisible friction.

Shiny new camera

Rotting door sill

The Compounding Interest of Neglect

Every postponed crack repair, every ignored leak, every patch on a crumbling floor is a loan taken against future productivity, future safety, future peace of mind. And the interest rates are extortionate. That tiny vibration from the old concrete slab under the new packaging machine? It causes microscopic wear on delicate components, requiring replacement every 24 months instead of the projected 44. Daniel D.’s jerry-rigged shims? They introduce small inconsistencies in the bread, leading to 4% more waste each week.

These aren’t just minor inconveniences; they’re compounding liabilities that silently erode profitability and efficiency. Ignoring these foundational elements is like building a skyscraper on quicksand, no matter how many luxurious floors you add. This is why investing in the underlying structure, like robust and resilient flooring, isn’t a cost; it’s a

The Glamour of the New vs. The Grunt of the Old

We prioritize the “new,” the “state-of-the-art,” often because it’s tangible, easy to justify on a budget line item that screams “innovation.” A new machine captures imagination. A renovated office space boosts morale *visibly*. But who champions the unsexy underbelly? Who gets excited about replacing the 44-year-old piping that occasionally bursts, or leveling a factory floor that’s seen 40 years of heavy traffic?

It’s not glamorous. The benefits are often measured in problems *avoided* rather than successes *achieved*, and that’s a harder sell to stakeholders fixated on immediate, quantifiable gains. Yet, the cost of deferring these critical infrastructure improvements is rarely calculated accurately. We might save $474 today by patching a problem, only to incur $4,444 in downtime and emergency repairs 4 months from now.

Patching Problem

Downtime & Repairs

The Unseen Foundation for High-Tech Flourishing

This isn’t just about maintenance budgets; it’s about a widespread tendency to devalue the foundational. In our rush to build bigger, faster, more advanced, we forget that the strength of the grandest structure is only as good as its weakest link at the very base. It’s a cultural blind spot, perhaps, driven by an economic model that rewards short-term gains over long-term resilience. We laud the visionary who installs the cutting-edge tech, but rarely the pragmatic leader who insists on repairing the underground utility lines before they fail.

The irony is, the more complex and precise our new technologies become, the more they demand a stable, predictable, and robust environment to truly flourish. A million-dollar sensor array is useless if its readings are constantly skewed by a vibrating floor. A high-speed robotic arm will wear out prematurely if its mounting point isn’t perfectly stable.

The Fallout: Morale, Safety, and the Perpetual Firefight

The fallout from infrastructural debt isn’t confined to financial statements. It seeps into employee morale. Imagine Daniel D., day in and day out, fighting against the building itself to do his job. How long until that wears him down? How long until he starts looking for a place where the basic tools of his trade aren’t constantly undermining his efforts?

Safety incidents spike. Remember the dust in the packaging plant? It’s not just an annoyance; it’s a respiratory hazard for the crew, and a slipping hazard if it mixes with any incidental spills. The hidden costs are staggering, extending far beyond the direct repair expenses to include lost talent, reduced product quality, and a general malaise that settles over an organization perpetually battling self-inflicted wounds. It becomes a story of constant firefighting, diverting precious resources from innovation and growth simply to keep things from completely collapsing.

Shifting Perspective: Valuing the Unseen

Acknowledging infrastructural debt means a fundamental shift in perspective. It means understanding that the quiet, unsung heroes – the maintenance crew, the facilities managers, the engineers who obsess over soil samples and stress loads – are just as vital as the product designers and the sales teams. It means recognizing that a strong foundation isn’t just a prerequisite; it’s a continuous investment.

It demands allocating budgets not just for what’s new and visible, but for what’s old, hidden, and absolutely critical. It’s about building a culture where preventative measures are celebrated, where foresight trumps frantic recovery. It’s about seeing the value in what prevents problems, not just what fixes them. This is the hardest part for many, myself included; the understanding that the most important work often goes unseen until it fails. I remember looking at that rotting sill and thinking, “How many times have I stepped over that? How many times have I *not* seen it?” Sometimes, the clarity only comes after a jarring impact.

Short-Term Focus

Visible Upgrades

Long-Term Resilience

Foundational Investment

The Compounding Question

So, how many invisible debts are you carrying in your own operations, silently draining energy and opportunity? What foundational elements are slowly eroding, just out of sight, waiting for the perfect moment to exact their compounding interest? The question isn’t whether you can afford to fix them, but whether you can truly afford *not* to.

Because the cost of doing nothing isn’t zero; it’s simply deferred, and it will always come due, with interest rates that would make any bank blush. And often, by the time we feel the earth shake, it’s already too late.

44x

The potential cost of inaction